In a few months, poultry farmers in Tsirang could start sourcing egg trays locally. A local poultry farmer is establishing an egg tray processing plant to support fellow farmers, who currently rely on supplies from other districts or India. The egg trays are expected to be cheaper.

In a few months, poultry farmers in Tsirang could start sourcing egg trays locally. A local poultry farmer is establishing an egg tray processing plant to support fellow farmers, who currently rely on supplies from other districts or India. The egg trays are expected to be cheaper.

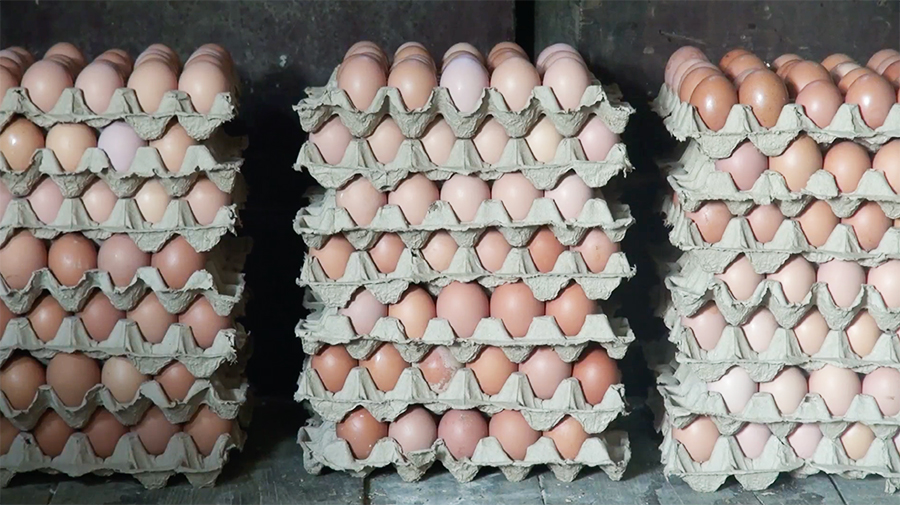

Tsirang is one of the country’s largest egg producers. Last year alone, the district produced nearly 700,000 trays of eggs.

Tsirang is one of the country’s largest egg producers. Last year alone, the district produced nearly 700,000 trays of eggs.

However, without a single egg tray manufacturer, local poultry farmers have had to buy trays from other districts or rely on imports, paying around Nu 450 to 500 per bundle, a cost they say is quite high.

At times, when feed agents or local dealers run out of stock, their business is affected.

But this could soon be a thing of the past.

57-year-old Dili Ram Waklay from Pemathang Chiwog in Gosarling Gewog is one of the poultry farmers in the district. After facing egg tray shortages five years ago, which affected his business, he decided to start manufacturing his own trays.

57-year-old Dili Ram Waklay from Pemathang Chiwog in Gosarling Gewog is one of the poultry farmers in the district. After facing egg tray shortages five years ago, which affected his business, he decided to start manufacturing his own trays.

Since then, he has been saving money and began constructing the processing plant earlier this year.

Dili Ram Waklay said, “Although the structure was completed, I couldn’t begin the production due to financial constraints to purchase the egg tray manufacturing machine. Currently, we sell unwanted cartons and papers to India, but once the factory becomes operational, we can make use of those unwanted cartons and papers here.”

Dili Ram Waklay said, “Although the structure was completed, I couldn’t begin the production due to financial constraints to purchase the egg tray manufacturing machine. Currently, we sell unwanted cartons and papers to India, but once the factory becomes operational, we can make use of those unwanted cartons and papers here.”

He is now buying the egg tray processing machine on a cost-sharing basis and expects it to arrive within the next few months.

Dili Ram has invested more than Nu 2.5 M in the project. Once operational, the plant is expected to produce about 500 egg trays per hour.

Dili Ram has invested more than Nu 2.5 M in the project. Once operational, the plant is expected to produce about 500 egg trays per hour.

He plans to sell the trays at a more affordable price compared to imported ones.

Dili Ram Waklay said, “I have been talking to people and decided to sell a packet of egg trays for between 350-400 ngultrum. With that price, I will also be able to make profits. I am also planning to improve the quality of egg trays by increasing their thickness, unlike the imported ones.”

Tsirang Poultry Cooperative, which has 43 members, said the upcoming egg tray processing plant will benefit them immensely.

“Currently, poultry farmers have to pay high prices for imported egg trays, considering its taxes and transportation costs. Having an egg tray processing factory within the district will greatly benefit farmers. Similarly, egg trays from other districts also cost more upon reaching Tsirang since sellers have to include transportation cost,” said Hom Nath Thapa, the accountant of the Tsirang Poultry Cooperative.

With a reliable supply of trays, poultry farmers hope to boost their egg business.

Pema Tshewang, Tsirang

Edited by Sangay Chezom