Drying fruits and vegetables could soon become faster and more efficient if the multipurpose electric dryer developed by Jigme Namgyal Engineering College reaches the market. A prototype of the dryer was presented yesterday during the National Outreach Workshop on Facilitating the Transfer of Appropriate Technology. The innovation aims to help reduce post-harvest losses.

Drying fruits and vegetables could soon become faster and more efficient if the multipurpose electric dryer developed by Jigme Namgyal Engineering College reaches the market. A prototype of the dryer was presented yesterday during the National Outreach Workshop on Facilitating the Transfer of Appropriate Technology. The innovation aims to help reduce post-harvest losses.

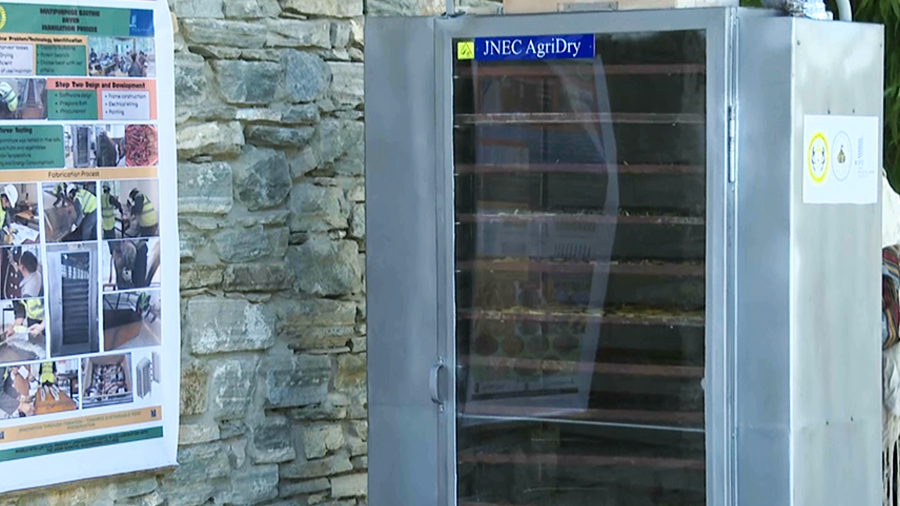

This multipurpose electric dryer, loaded with trays of vegetables, has been running since morning.

This multipurpose electric dryer, loaded with trays of vegetables, has been running since morning.

By late afternoon, the vegetables were crisp, aromatic, and perfectly dried.

The dryer has fifteen chambers with adjustable heating to efficiently control temperature and airflow to ensure uniform drying.

The dryer expects to reduce post-harvest loss. According to the Ministry of Agriculture and Livestock, farmers in the country lose nearly 40 per cent of their fruits and vegetables to spoilage after harvest.

“This is a simple technology; anyone who buys it can easily maintain it. Another thing is that it is a green technology since it only uses electricity,” said Deo Raj Biswa, a lecturer with Jigme Namgyal Engineering College, Samdrup Jongkhar.

Traditional sun-drying or small wooden and metal dryers are slow and weather-dependent.

The imported electric dryers in the market provide temporary solutions. However, people say they are costly, difficult to maintain, and vulnerable to damage.

Tashi Wangmo, a member of the Khenrig Namsum Cooperatives, said, “The dryer can dry fruits and vegetables in just one day while preserving their natural colour. In comparison, the imported dryers we have take around three days due to their larger capacity. Although this dryer has a smaller capacity, it ensures that the end products retain their natural colour and quality.”

The dryer is energy-efficient as well.

The college plans to produce the first 10 electric dryers after securing funding and later license the technology for wider commercialisation.

“A key feature of this project is that it connects the protection of ideas with building technical skills. This leads to practical technologies, like this dryer, that can be developed and used to meet the needs of local communities,” said Purevdorj Vaanchig, the head of the Coordination Unit for LDCs, World Intellectual Property Organisation.

“To take innovation and technology transfer to a bigger scale, we can work with a lot of partners. Firstly, we can work with government agencies. We, as an academic institution, have limited funding, so we can work with all these agencies to get funding,” said Tashi Wangchuk, the dean of Jigme Namgyal Engineering College.

Simple and eco-friendly technologies like this show how homegrown solutions can make an impact on rural livelihoods and drive the nation’s self-reliance.

The National Outreach Workshop on Facilitating Transfer of Appropriate Technology was organised by the World Intellectual Property Organisation in collaboration with Jigme Namgyal Engineering College.

The National Outreach Workshop on Facilitating Transfer of Appropriate Technology was organised by the World Intellectual Property Organisation in collaboration with Jigme Namgyal Engineering College.

Kinley Bidha

Edited by Sangay Chezom